When handcrafting a piece of clothing, attention is paid to every detail, from material choices, to cut, to construction technique. Wearing, touching, and seeing these details in person is really the best way to get to know them. Although it may not be conveyed quite so well via image, while working on a standard men's shirt (

custom ordered in this particular fabric), I captured some of the details in-process.

|

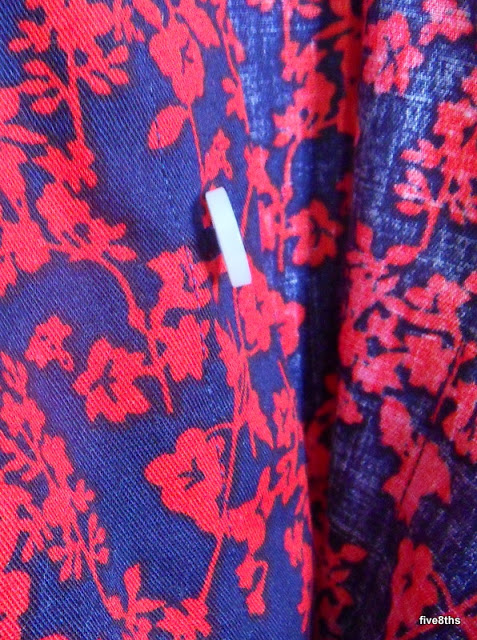

| The five8ths logo and size are manually embroidered on the inside yoke. |

|

| The bottom edge of the shirt is finished with a rolled hem. |

|

| The front band is finished at the hem with a triangle point on the inside of the shirt. |

|

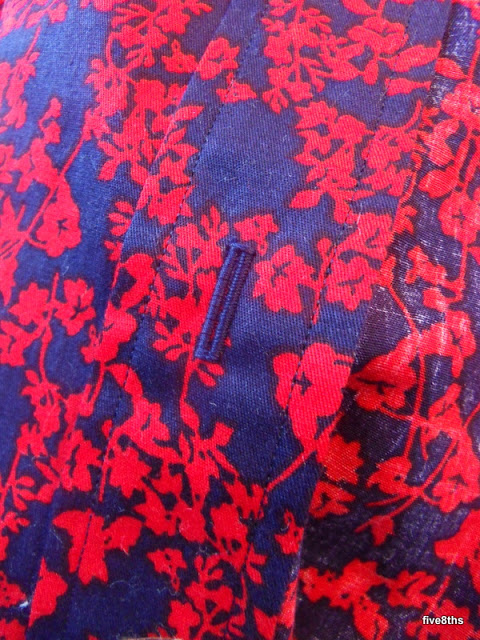

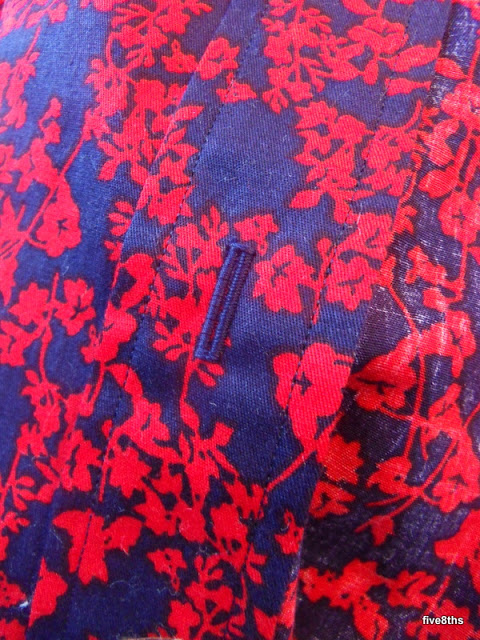

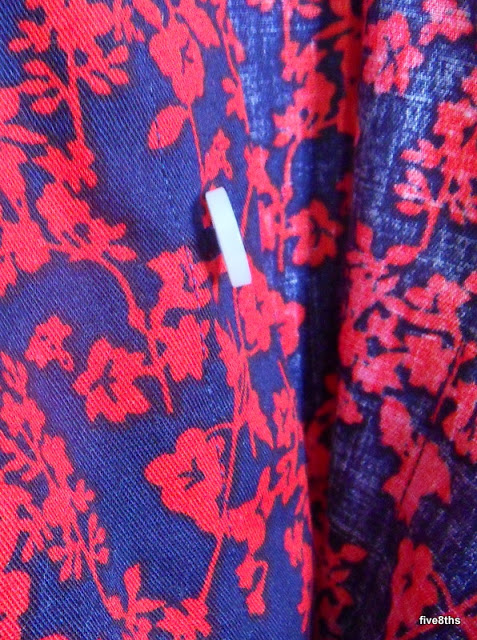

Collar-stay slots are sewn into the

under-collar.

|

| The collar is eased so that it rolls both around the neck and over the fold, and maintains that form on its own. |

|

|

|

The sleeve-placket is fastened with a button.

|

|

| Sleeve placket |

|

| The hem edge of the side-seams are finished with a contrasting placket. |

|

| Beautiful, Bernina 830 Record buttonholes on the front band. |

|

| Buttons are sewn on by hand, and finished with a thread shank. |

|

| An extra button is included with every shirt, sewn to the inside of the front band (so it's easily found when needed). |